Special all-season mineral hydraulic oils created for hydraulic devices of stationary or mobile equipment operating at high and very high operating temperatures. It was developed taking into account the requirements for industrial hydraulic systems operating in the conditions of very high loads, pressures, temperatures and/or velocities.

Product properties:

- It contains antiwear, anti-oxidising, anticorrosion and antifoaming additives.

- It has good antiwear properties that minimise the wear of the parts related to hydraulic pumps thus ensuring their long service life. It reduces the traction in gear shift mechanisms, bearings, pneumatic equipment;

- Modern cleaning-dispersing additives ensure an ideal cleanliness of the hydraulic system parts thus also protecting precision pairs from wear, extend the equipment life;

- A high thermo-oxidative and thermal stability reduce the formation of all types of deposits and corrosive substances that increase the reliability of the subsystems’ operability (valves, hydraulic directional valves, etc.) and simultaneously distinguishes itself by an excellent filtering ability;

- Due to good anticorrosion properties, it protects surfaces of all used metals and alloys against a corrosive impact of acids and water that significantly reduce the maintenance and repairs costs;

- It is characterised by excellent demulsifying properties, sufficiently low freezing point and a long service life;

- The resistance to foam formation enhances the efficiency of hydraulic pumps;

- It is neutral in regards to all sealing materials and paint-and-lacquer coatings compatible with mineral oils. It prevents leakages thus reducing buying costs.

It is recommended to be used as a power fluid for industrial hydraulic systems:

- Stationary equipment (pressing machines, elevators, moulding machines, robots, industrial machines, forming machines, gear transmissions, pneumatic systems, etc.);

- Mobile equipment (construction, highway, mining, tree harvesting, various municipal and special equipment, etc.);

- The following types: DENISON, EATON VICKERS, GEROTOR, GRESEN, HPM, CESSNA, HYDRECO, WORTHINGTON, etc.

- Where there are syringe, geared, impeller, axial piston pumps in compliance with manufacturer’s requirements;

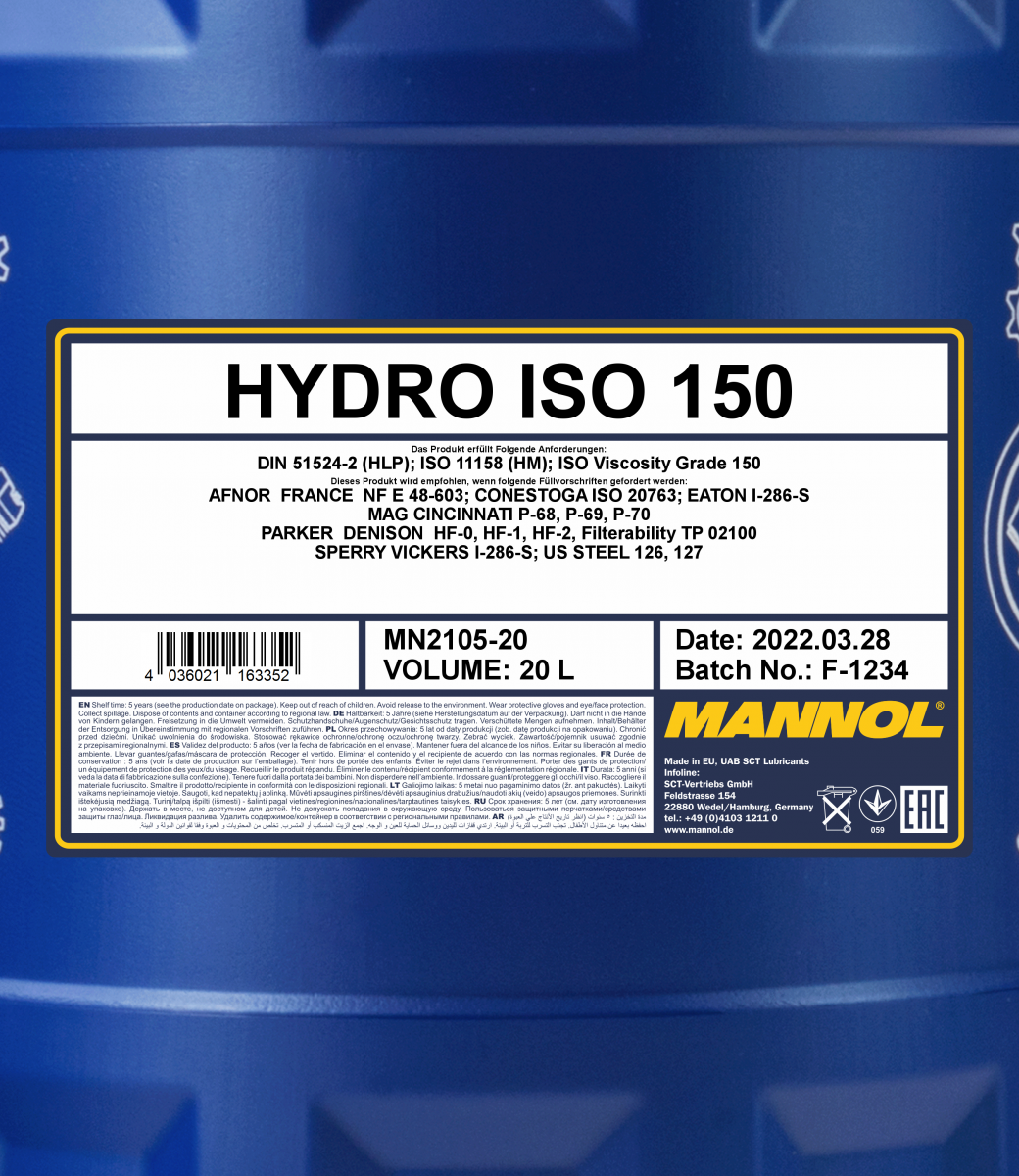

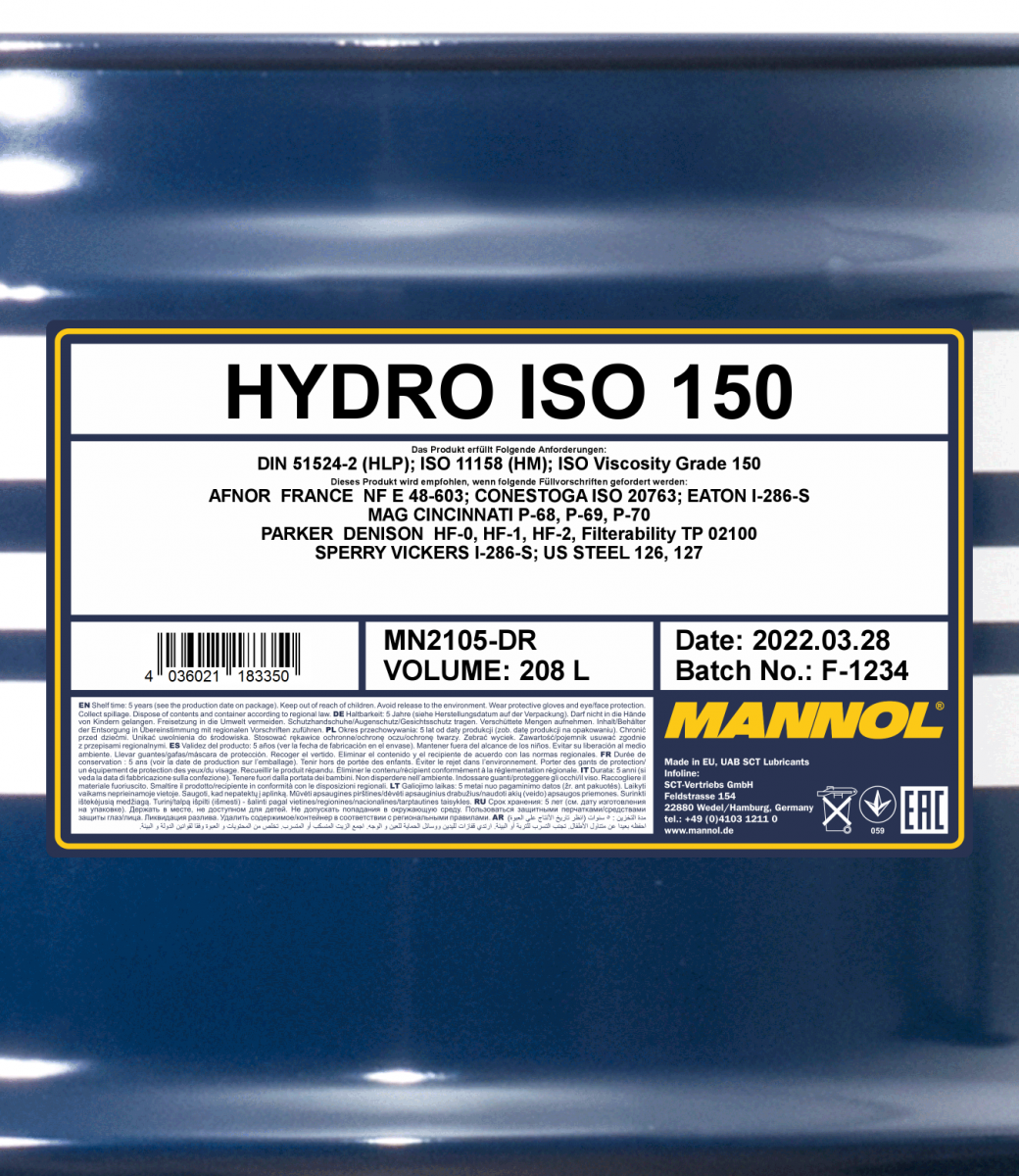

- When the oil standards DIN 51524 Part 2 (HLP) or ISO 11158 (HM) are required to be used.

In order to properly use it, thoroughly read the user’s manual of the equipment especially on the operating temperatures!